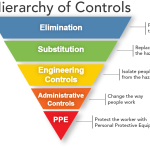

Hierarchy of Controls for Safety

Hierarchy of Controls for Safety

Controlling exposures to occupational hazards is fundamental for protecting workers. Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective safety controls.

A widely used representation of this hierarchy can be summarized as follows:

- Elimination

- Substitution

- Engineering controls

- Administrative controls

- Personal protective equipment (PPE)

The idea behind this hierarchy is that the control methods at the top of the list are potentially more effective and protective than those at the bottom. Following the hierarchy normally leads to the implementation of inherently safer systems where the risk of illness or injury has been substantially reduced.

Elimination and substitution, while most effective at reducing hazards, also tend to be the most difficult to implement, especially in existing systems and processes. In situations where processes are still at the design or development stage, elimination and substitution of hazards may be simple and inexpensive to implement. For existing systems, however, major changes in equipment and procedures could be required to eliminate or substitute a hazard, which can be a significant expense.

Example: Look everywhere for the possibility of elimination. Elimination of a hazardous chemical may not be feasible due to the requirement of that particular chemical for its chemical reaction but, there may be other less obvious instances where a chemical may be substituted for a less hazardous chemical, such as substituting with less toxic cleaner in a cleaning step. Another example may be compromise. One of our clients had a customer that wanted their materials packed in a specific container. Our client attempted to meet their customers’ desires by packing in this specific container. The container was awkward to fill and did not fit the ergonomic design of the packing area, making it hazardous long term. Our client worked with their customer to determine why the customer wanted this specific packaging. Once the need was understood, our client came up with a solution that met the needs of the client and was ergonomically correct, therefore not hazardous to the packing team.

Engineering controls are used to remove a hazard or place a barrier between the worker and the hazard. Well-designed engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection. The initial cost of engineering controls can be higher than the cost of administrative controls or personal protective equipment (PPE), but over the longer term, operating costs are frequently lower, and in some instances, can provide a cost savings in other areas of the process.

Example: Ventilation or air scrubbers will capture toxic fumes and keep the fumes from contacting the workers, controlling the chemical at the source. Other engineering controls might be physical barriers to keep the chemical from contacting the workers. Other common engineering control examples are cases where there is older equipment. Often the older equipment works well, however machine guarding is no longer effective or non-existent. In many of these cases, older equipment can be retrofit with photo eyes, pressure sensors, and other technically advanced guarding equipment.

Administrative controls and personal protective equipment are frequently used with existing processes where hazards can not be controlled by elimination, substitution or engineering. Administrative controls are policies and/or procedures which explain how to perform a job or task. They may outline things such as job rotation, proper handling techniques or performing tasks in a particular order. PPE refers to protective clothing of all sorts, click here for definition and list of examples. Administrative controls and personal protective equipment programs may be relatively inexpensive to establish but, over the long term, can be costly to sustain. When only these methods for protecting workers are used, they have proven to be less effective than other measures, requiring significant effort by the affected workers. The use of PPE doesn’t eliminate hazard, it only serves as a barrier. If the barrier is breached, the worker is exposed to the hazard.

Example: We have found that a great use of administrative control is when a job is repetitive. Mental and/or ergonomic repetition can be dangerous. Mentally when you do something over and over, no matter how diligent you are, you tend to start thinking about other things, it’s natural. When you are not focused on the job or task it’s easy to make mistakes and/or hurt yourself. Ergonomically when you do something over and over again the body breaks down faster in the area getting used repeatedly eventually causing injury. Implementing job rotation will alleviate repetition. Rotation can be managed several ways depending on the situation. You could rotate the people, the tasks, and the order of operation whenever possible.

Example: As we’ve mentioned, PPE does not eliminate hazards which makes PPE the last line of defense. Whether you have controls for existing PPE or the potential for PPE use, PPE should be re-evaluated on a regular basis. In some cases we found that although gloves were being used, the best gloves for the job were not being used and changing the type and/or fit of the glove reduced injuries by 100%. In other cases where hearing protection was being used, some engineering controls were changed and higher decibel protection was needed.

Take time at the beginning of new projects to determine what will be the most effective method for controlling hazards. Before its necessary, take time to implement new controls in existing systems. Start at the top and work your way down. Don’t fall into the trap of using PPE protection when other methods can be implemented. Eliminate risk when and where ever possible.